| Gradual Evolution is a powerful synthesis tool in situations where the total thickness of the current design is insufficient to achieve the desired value of the merit function or in situations where the user wants the program to synthesize a design from a very simple starting design or even without any starting design. The Gradual Evolution Setup window allows the user to specify as termination criteria the value of the merit function, the maximum physical or/and optical thickness or the maximum number of layers in the final design.

In the Gradual Evolution process, an additional thick layer is automatically inserted in the design when the needle optimization is over and termination criteria are not yet satisfied. The insertion can be done near the substrate, near the incident medium, or somewhere inside the design. The material and thickness of additional layer are chosen automatically. Note that after the insertion of a new layer the value of the merit function usually increases. Once the new layer is inserted, automatic needle optimization restarts. The Needle Optimization process runs until one of the termination criteria has been satisfied. If the Needle Optimization process stops and termination criteria are not yet satisfied, then another thick layer is added and another cycle of the process continues. Gradual Evolution (advanced) allows experienced users to design multilayer coatings with sophisticated requirements on layer thicknesses and layer materials. Note, that no starting design is necessary in order to run Gradual Evolution. It is necessary only to load target data, substrate, and at least two layer materials. OptiLayer synthesizes your coating automatically in an optimal way. Read more in:

|

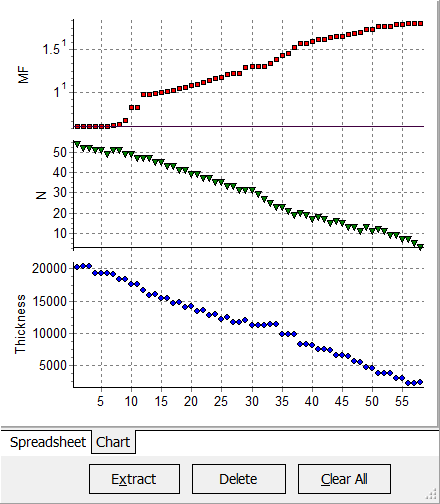

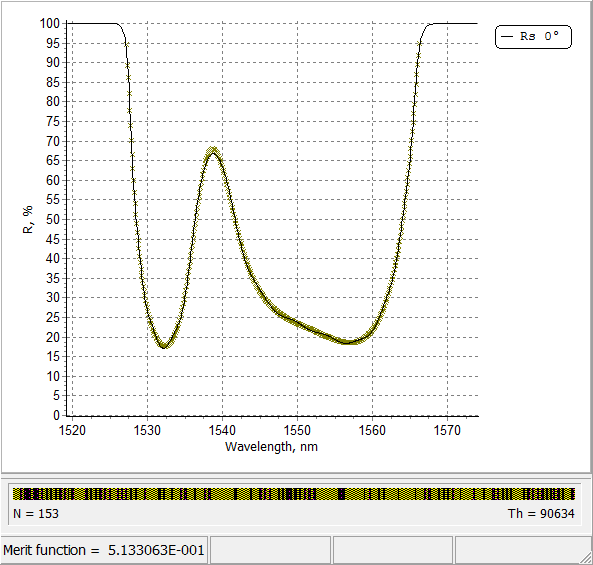

Evolution of coating thickness, number of layer and merit function in the course of synthesis of Gain Flattening Filter (GFF). |